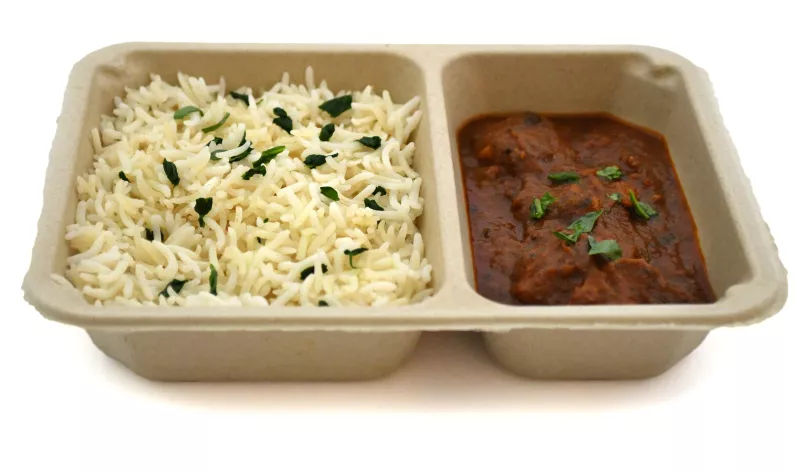

Ovenable Packaging

Non-bleached, 100% renewable, molded-fiber trays, plates, and bowls bring sustainability to fresh and frozen ready-meals.

Renewable, Sustainable and Dual Ovenable

Available exclusively from Sonoco in the U.S., Natrellis plates, bowls, and trays are made with U.S.-grown plant fibers primarily resulting from sugar-cane processing and sourced through Tellus Products LLC.

The Natrellis portfolio combines responsible sourcing of 100% renewable raw materials with a dual-ovenable structure perfect for applications frozen or chilled ready-to-cook foods that can bring convenience, freshness, and sustainability to any meal.

We support your sales goals through:

Performance

Temperature Stability - Dual Ovenable

- Microwave: 1100 watts / 10 minutes

- Conventional: up to 400F / 30 minutes

Moisture/Oil and Grease Resistance

- No wicking or moisture loss

- Package strength during all phases of use

- Ensures optimum shelf life

Heat Sealability

- Rigid or flexible film lids available

- Edge and rim design prevents leakage prior to freezing

- Easy for consumers to grasp and peel back

Designed as a Drop-in Solution to Existing Lines

- Compatible with hot roller and platen technologies

Sustainability

Renewable Resources

- Made with 100% renewable, sugarcane and other plant-based fibers

- Tellus sugarcane fibers are post-industrial recycled materials collected from sugar milling process

Limited Carbon Footprint Manufacturing

- Tellus facility powered with combination of solar energy and biomass

Natural Appearance and Components

- Unbleached fiber

- No fluorocarbons (PFA) of any kind

Serving global customers in a global world.

We offer injection molded tub design, prototyping, mold-making, production and assembly in the U.S., Mexico, the Netherlands and Germany. No one is more committed than we are to meeting our customers’ needs around the world.

More than 50 years ago, Sonoco was one of the first to venture into the brand new technology of injection molding. Today, we maintain a focus on innovation, making 95% of our products with custom injection molds.

Connect with Sonoco

Learn more about our ovenable packaging options. We're eager to discuss how we can help you meet your customers' needs and your business goals.